|   Home Home

Bike

WorkShop Bike

WorkShop

BB's

and Cranks BB's

and Cranks

Brakes Brakes

Chains Chains

Cleaning

and lubrication Cleaning

and lubrication

Mavic

Crossrides Mavic

Crossrides

GT

Idrive GT

Idrive

Pre

Ride Checks Pre

Ride Checks

Punctures Punctures

RST

Forks RST

Forks

Size Size

Small

Tips Small

Tips

Suspension Suspension

Wheels Wheels

Riding

Tips Riding

Tips

Play

Areas - EA Play

Areas - EA

Play

Areas - Other Play

Areas - Other

Routes

- EA Routes

- EA

Routes

- Other Routes

- Other

Reviews Reviews

Ride

Reports Ride

Reports

Health Health

Gallery Gallery

Videos Videos

Links Links

Our

Bikes Our

Bikes

|

RST ELASTOMER

FORKS

After purchasing my RST 461 I found

the sever lack of info on the forks to be a problem, RST are very

good at answering problems but some pointers in the right direction

would be nice. The tips on this page should apply to all the RST Elastomer

forks including the 280,281,381 and 461 series of forks.

SERVICING

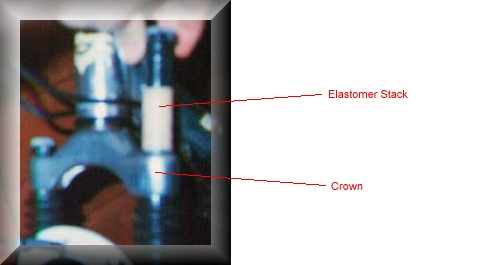

Diagram

of RST 461 Internal Layout

These

forks need servicing every 20-25 hours off road time. The manual that

RST provides is dire (well mine is) and the first thing that it tells

you to do is loosen the crown bolts, RST forks don't have crown bolts

any more. When I next service my forks (I've only just done it and

that's what prompted me into writing this page) I'll include some

nice pictures for you to see.

Doing

a routine service on these forks is a lot easier than some none RST

forks so here we go.

- Before you

start remove the wheel and the brake cable from the brake levers,

this will make pulling the lower legs a hell of a lot easier.

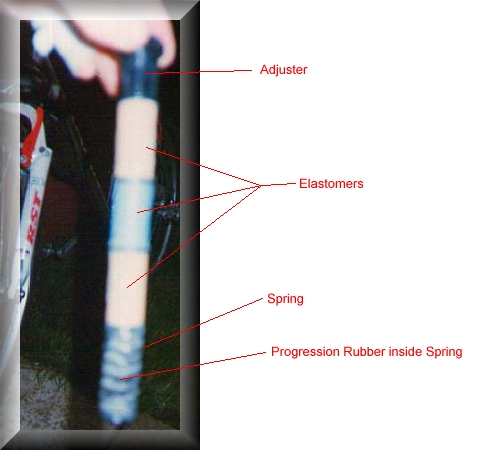

- Unscrew the

adjuster stacks from the fork, you will probably need to use a

adjustable spanner to got the size correct, make sure that you

undo them correctly as they only have plastic threads and plastic

is weaker than steel, don't want to strip the thread on these.

Once you have undone the adjuster's you will be able to pull the

elastomer stacks from the forks.

- At the bottom

of each leg, is a bolt remove these with a 4mm hex key. If you

look down the forks from where you have just removed the elastomer

you will be able to see a 8mm hex bolt hole, it may be necessary

to hold this in place with a 8mm hex key whilst undoing the 4mm

bolt at the bottom of the legs.

- Remove the

boots from the lower legs so they stay on the stanchions, this

will make refitting a whole lot easier.

- Pull up the

boots and sharply separate the lower legs and the stanchions.

- Thoroughly

clean the stanchions and the elastomer stacks, I dissemble my

elastomer stacks when doing it as this makes it a lot easier to

clean the last of the grease out, basically they just pull apart

as there are plastic spacers in between.

- Grease the

seals and bushings in the lower legs and the elastomers using

a non-lithium grease, lithium grease damages the elastomers and

actually doesn't work very well. RST recommend Arlo Englund's

Slick Honey and Bel-Ray, I use PACE and that seems to work as

well as it gets.

- Grease the

bump stops and the drop outs at the bottom of the stanchions and

rebuild the forks.

UPGRADING

RST Elastomer forks are fairly

stiff and have room for a few changes, on the average ride the fork

should bottom out a couple of times, if you don't you are not using

all of your travel and have room to experiment. Please note that I

cannot take responsibility for any damage done by doing any of the

following.

- Replacement Elastomers can be bought, these

change the softness of you forks

- One alternative to Replacing elastomers

is to place them on a lave, and cut a few shallow rings around

them, this will make them easier to compress and allow them to

be compressed further before they 'Jam' together thus improving

the travel on your forks

- Boil the elastomers in water for 5 mins,

this reduces the amount of nitrogen in them and improves

performance

- In the springs at the bottom of the elastomers

is a piece of rubber, the spring handles the small dumps and the

rubber provides the progression of movement to the elastomers

on larger bumps, so the further the spring compressed the more

the elastomers are compressed so that it feels like a progressive

movement rather that Sprint/elastomer. Removal off one or both

(one in each leg) or reducing the size of the rubber may increase

you small bump response. On forks without air damping removal

of this piece of rubber may cause the shock to fell like a pogo

stick on small bumps as it seems to jump about. Reducing the size

of this on none air damped forks may increase your small bump

response while still allowing for progressive of bump to the elastomers

transfer, if in doubt try to source a piece of rubber that you

have use instead rather then destroy the ones that you bought

with the forks. I removed one on my 461's and didn't like the

response. I then reduced the size of both rubbers and it felt

that the fork dealt with repeating small bumps better.

- Reducing the size of the bump stop rubbers

(in the springs at the bottom of the elastomer stack) and the

bottom and inside of the stanchions can improve the travel on

the forks, best way thought is to source replacement rubbers so

that you can go back if you don't like.

DON'T

- Don't use Lithium grease it doesn't work

and it damages your elastomers

- Don't use Vegetable oil, it isn't sticky

enough to stay in the tops of you forks and you will find that

some area of you forks are not lubricated

- Don't use a mixture of grease and oil,

you will end up with a sticky mess that you cannot remove from

your forks

|